Quality Assurance

Image Inspection

-

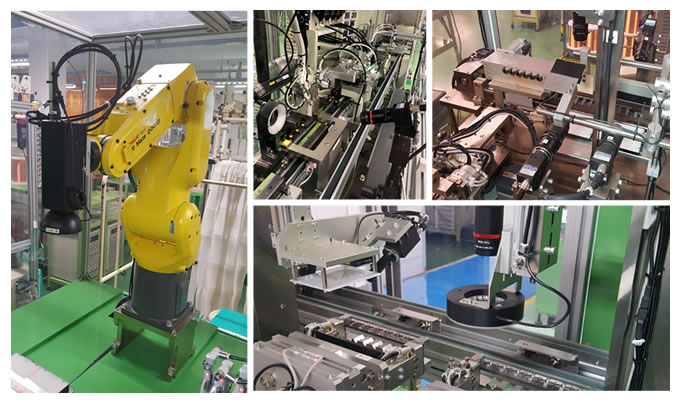

We optimize the image inspection process depending on the coil shape.

Inspections are conducted from various angles by changing the position of cameras and coils.

Air cleanliness

-

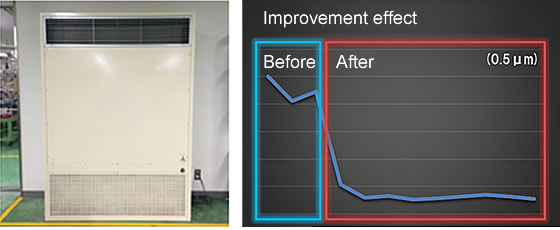

The environment of the plant has been enhanced through the introduction of a clean unit, etc.

(Cleanliness of Class 100,000 [0.5 µm] is maintained and controlled.)

Analysis

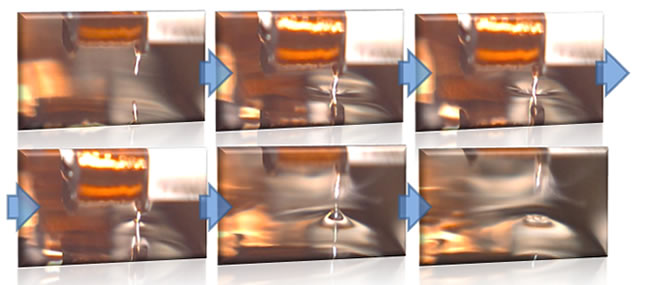

Case 1 (High-speed camera)

- A high-speed camera is used to check the operation in slow motion. This helps analyze phenomena that cannot be detected otherwise and improve quality.

- The images above were used to analyze an upward flow of solder in the coil soldering process.

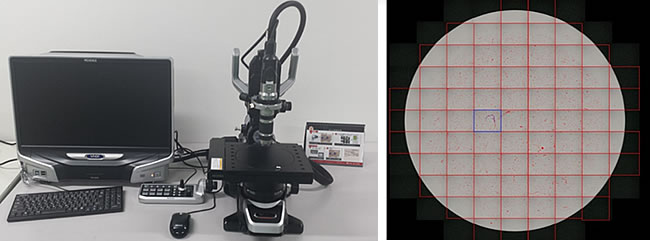

Case 2 (Microscope [ filter paper test ])

- Foreign matter that adheres to coils is automatically counted to improve the analysis efficiency.

Electrical properties inspection

- Resistance, withstand voltage, layer short circuit, impedance, and inductance can be measured depending on the coil specifications.

Image dimension measuring device

- This equipment is installed on each floor to eliminate dispersion in manual measurement and improve the work efficiency.