Technology

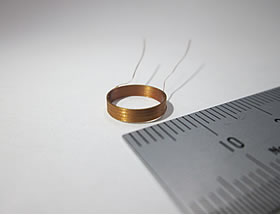

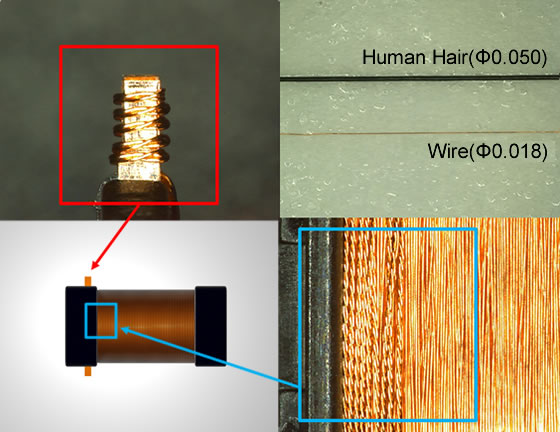

Ultrafine wires

- We can wind ultrafine wires (minimum diameter: 0.018 mm).

- Automatic strand processing helps avoid the risk of breakage at the ends.

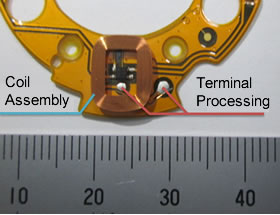

Terminal processing

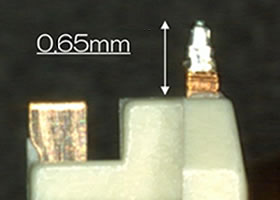

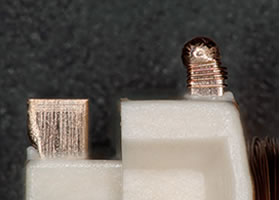

-

Binding and soldering can be performed

for a terminal length of 0.65 mm. -

We use arc welding to meet the need

for highly heatproof specifications.

Other terminal processing such as fusing and laser. Inquiries are always welcome.

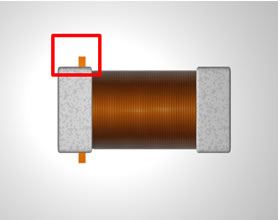

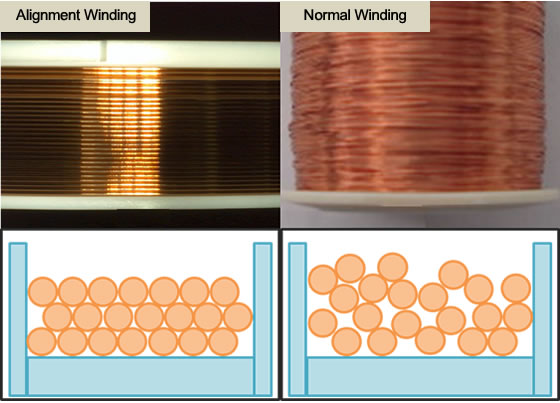

Alignment Winding

- Complete regular winding helps keep the electrical characteristics constant.

- Uniform winding helps increase the coil space factor and reduce the space required.

- Multi-axis winding machines achieve mass production with complete regular winding.

Edgwise coil *1

-

The large coils are designed for large currents.

Rectangular wires are wound layer by layer. Coils of a high coil space factor can be manufactured.

An increased coil space factor helps improve the performance and downsize products. -

Circular and race-track coils are also available.

We have a track record in manufacturing coils using thick and thin rectangular wires.

Edgwise coil (Self-bonding Flat Wires)

- Wires are wound layer by layer as in the case of the coil above (*1). The coil shown in the photo is made from a □ 0.03 mm × 0.17 mm rectangular wire.

Assembly

- We can also undertake the work in subsequent processes such as assembly of a coil to a flexible printed circuit. Inquiries are always welcome.

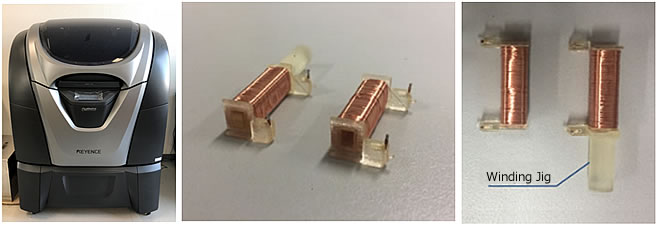

3D printer

- We assist customers in prototype development using a high-performance 3D printer.

- Product development efficiency can be increased by making prototypes (through fabrication of bobbins) and checking the fitting with other parts.